The A320 ATA 47 Technical Notes provide brief and to-the-point information about the Airbus A320 Inert Gas System, including its components and their functions. ATA Chapter 47 deals with the Nitrogen Generation System that reduces the risk of fire and explosion in the center wing-box fuel tank by introducing nitrogen into the empty space of the fuel tank.

The terms “Inert Gas System”, “Nitrogen Generation System”, and “Fuel Tank Inerting System” are all related to ATA 47. They refer to different components or aspects of the same system:

- The Inert Gas System (IGS) is a general term for a system that reduces the amount of oxygen in a specific environment (in this case, the aircraft’s fuel tank) to decrease the risk of fire or explosion.

- The Nitrogen Generation System (NGS) or Inert Gas Generation System (IGGS) is a subsystem of the Inert Gas System. It filters conditioned air to produce Nitrogen Enriched Air (NEA) and Oxygen Enriched Air (OEA). The NEA is introduced into the fuel tank, while the OEA is vented overboard.

- The Fuel Tank Inerting System (FTIS) is another name for the Inert Gas System. It specifically refers to the system used to reduce the oxygen levels in the aircraft’s center fuel tank.

A320 INERT GAS SYSTEM

The Fuel Tank Inerting System (FTIS) is a method used to reduce the risk of fire and explosion in the center wing-box fuel tank by lowering the Flammability Exposure of the fleet to acceptable levels. This is achieved by creating non-flammable (inert) conditions in the ullage space of the fuel tank, where ‘ullage space’ refers to the space/area above the fuel.

The FTIS supplies inert gas into the fuel tanks and this causes all oxygen to flow out of the tanks. This reduces the flammability in the fuel tanks.

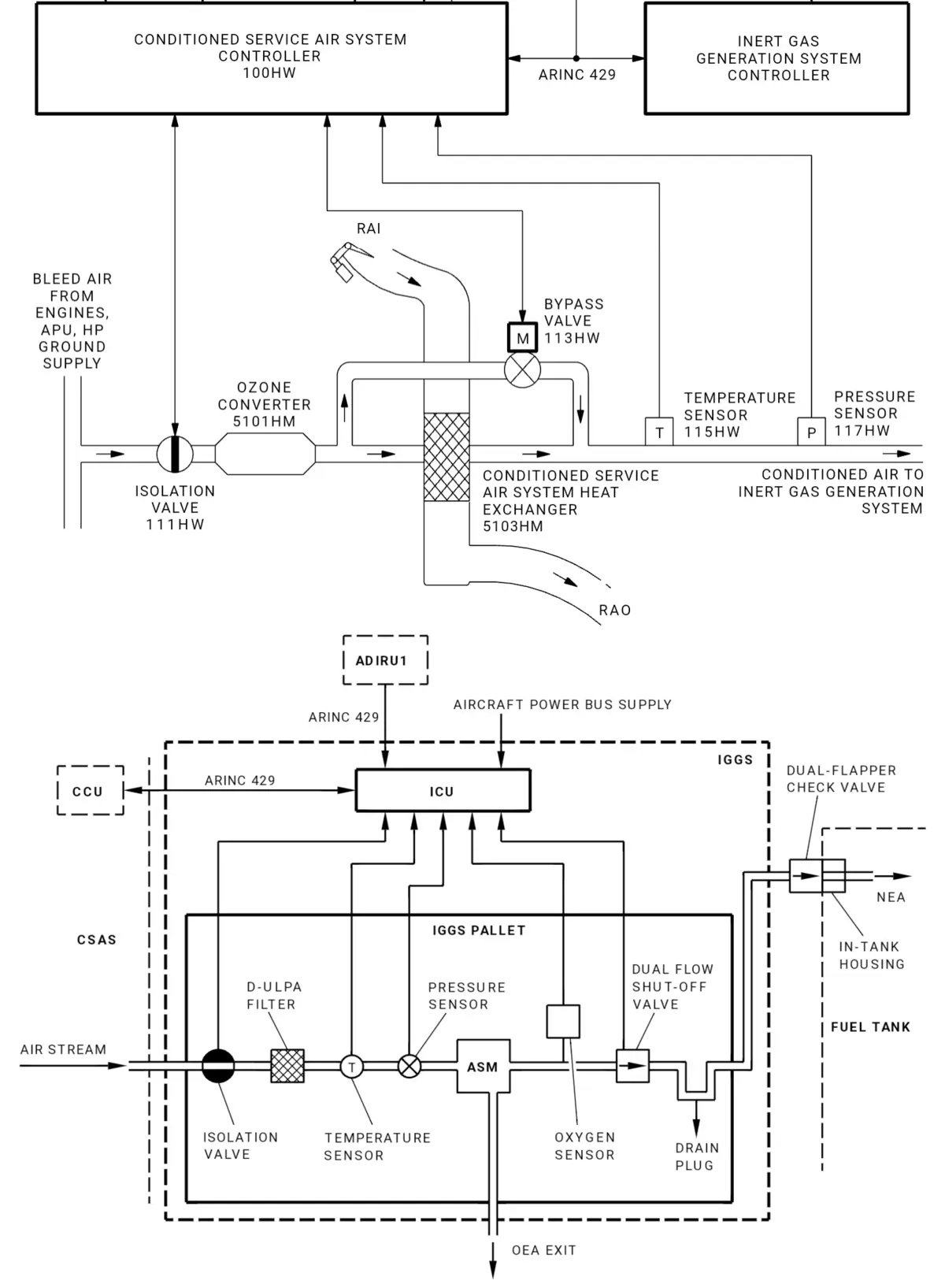

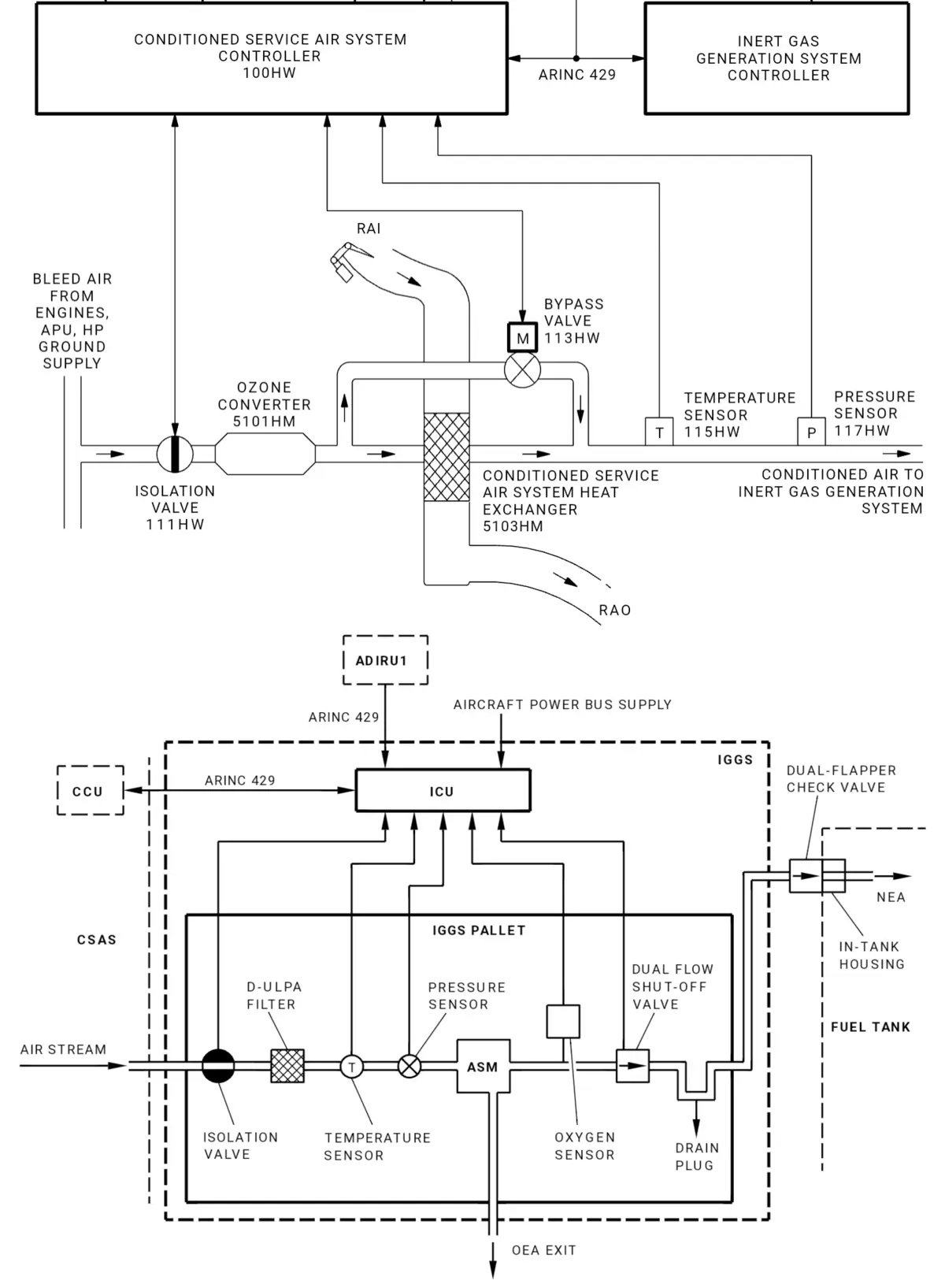

The Airbus A320 FTIS consists of two sub-systems, the Inert Gas Generation System (IGGS) and the Conditioned Service Air System (CSAS).

- Reduces the amount of oxygen in the air within the center tank.

- Fuel Tank Inerting System (FTIS)

- Conditioned Service Air System (CSAS) – ATA 21

- Inert Gas Generation System (IGGS) – ATA 47

The Conditioned Service Air System (CSAS) supplies the Inert Gas Generation System (IGGS) with an air stream that has been adjusted to the appropriate temperature, pressure, and flow. The IGGS then removes oxygen from this air stream, producing Nitrogen Enriched Air (NEA) and Oxygen Enriched Air (OEA).

The Inert Gas Generation System (IGGS) discards the OEA overboard and puts the NEA into the ullage space of the fuel tank. Nitrogen is a chemically unreactive gas because it does not support the hydrocarbon combustion reaction, and it is non-reactive with the materials of the fuel system components and equipment.

A320 FTIS Schematic

CSAS

Hot Bleed Air > CSAS Isolation Valve > Ozone Converter > CSAS Heat Exchanger (TCM) > Conditioned Air

- CSAS Controller Unit (CCU)

- Controls CSAS Isolation Valve

- Interface with IGGS Controller Unit (ICU)

- Has BITE function of CCU

- Also has BITE functions of ICU

IGGS

Conditioned Air > IGGS Isolation Valve > D-ULPA (Double ultra low particle) filter > Air Separation Module > NEA + OEA

- NEA > Dual Flow Shut Off Valve > Dual Flapper Check Valve > Center Tank

- OEA discards overboard.

- Dual Flow Shut Off Valve, two function –

- Open/Shut for NEA

- Controls NEA Flows

- Low – Climb and Cruise

- Mid – Approach

- High – Descent

- IGGS Controller Unit (ICU) – Controls IGGS Isolation Valve

- Oxygen sensor – measures the oxygen concentration of the NEA.

KEY POINTS

- The ozone converter catalytically decreases the ozone concentration of the bleed air. The decreased ozone concentration prevents damage to the air separation module fibers of the inert gas generation system.

- The CSAS Temperature Control Module (TCM) has:

- a CSAS heat exchanger,

- a hot air bypass valve,

- a temperature sensor,

- a pressure sensor.

- TCM is installed on the ram air inlet side of the air conditioning pack 1 heat exchanger.

- IGGS Pallet – a structural support made of aluminum, contains the isolation valve, D-ULPA filter, ASM, oxygen sensor, and Dual Flow Shut-Off Valve.

- The fuel tank is inert when the average oxygen concentration is below 12% at sea level.

- The aircraft crew does not operate the FTIS, because it has automatic control.

- When the aircraft is on ground the FTIS does not operate.

- During aircraft flight, the FTIS operates automatically.

- CSAS is required to cool down hot bleed air at a level compatible with IGGS.

- CSAS is an air temperature conditioning system that cools the hot engine bleed air.

- CSAS is part of the FTIS, You can find CSAS in ATA 21 of the Airbus A320.

COMPUTERS

- CSAS Controller – 1

- IGGS Controller – 1

See the location of A320 Computers.