Aircraft Walk Around contributes to maintaining the safety of the aircraft.

Aircraft Exterior Inspection

The exterior inspection is done to make sure that the overall condition of the aircraft and the components and equipment that can be seen are safe for the flight. The instructions for the checks that must be done are in the FCOM.

The maintenance personnel usually does a full inspection before each originating flight. If no maintenance personnel is available, a flight crew member does the full inspection.

- Do a check of the structure for impact damage.

- Do a check for signs of fuel, oil, or hydraulic leaks.

The flight crew must perform a complete walkaround before each flight. The parking brake must be set to ON during the exterior walkaround, in order to enable the flight crew to check brake wear indicators.

- There is no impact damage to the structure

- There is no evident fuel, oil, or hydraulic leak

- All ground access doors are closed

What to look for

Examples of items to pay attention to:

- Cargo and servicing access doors areas which have been operated during the aircraft ground time.

- Evidence of leaks of hydraulic, fuel, oil or water/waste.

- The condition of aerodynamic seals.

- Wear and erosion.

- Foreign Object Damage (FOD), and bird strike.

- Missing service doors, access panels, or static wicks.

- Structural damage.

- Anomalies, vent obstruction, and missing placards.

- Lightning strike damage.

Where to look

Examples of areas to pay attention to:

- Door frames, passenger and cargo compartments.

- Drains, engines, and APU.

- Leading edges, wings, THS, slats and flaps.

- Landing gear, brakes, and tyres.

- Engines air intakes and fan blades.

After a night stop or transit where maintenance activities could have been one, it is very important to perform a last walk around to check all what was approached or touched after the area is cleared by all the personal, e.g.:

- fan cowls latching,

- fuselage doors for damage,

- service panels for secured latches,

- fuel cap installation, and

- no abnormal details.

Clean, pick-up debris on the apron so that they can not be sucked in by an engine, or causing tyre damage. Correct findings without delay to avoid further deterioration.

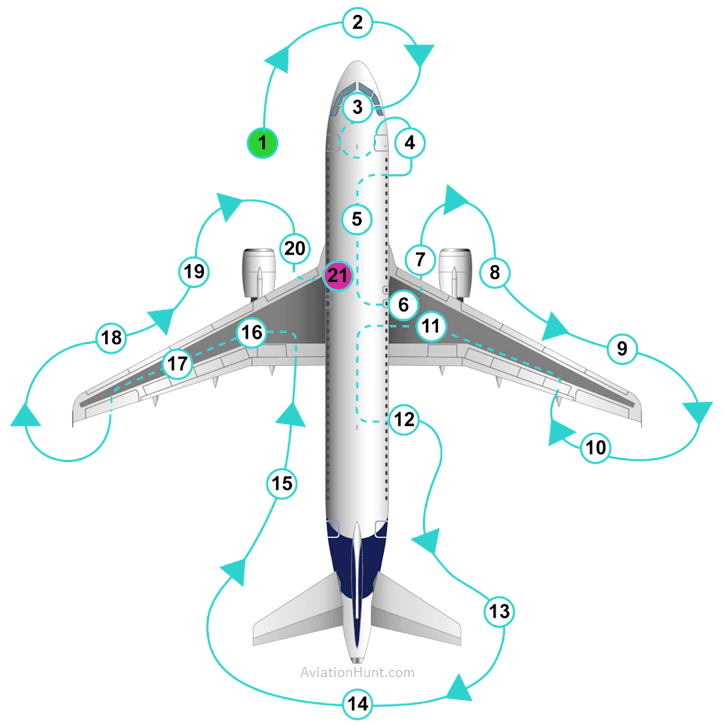

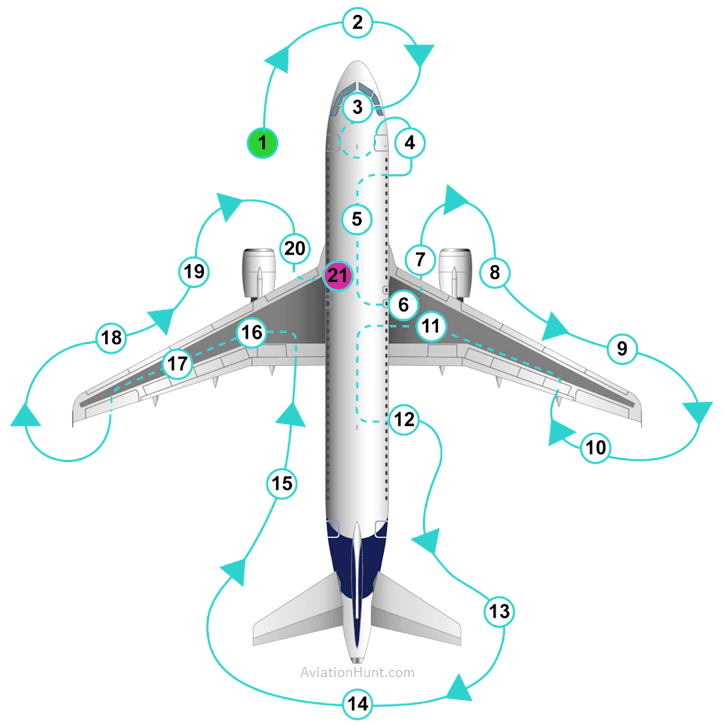

Airbus A320 Walkaround

How to proceed – walk around

- Start your walk around following a predefined way to ensure to view all the areas.

- While walking in one direction, look also back to see the hidden side of flap fairings for example.

- Focus on the areas more exposed to possible findings.

- Hydraulic and oil level checks can be used as an indication of possible fluid loss.

- Adverse weather, night, sun reflection on the fuselage have your attention level to be raised.

- Avoid distraction during the walk around.

- Record the work performed, initiate corrective action plan, and ensure parts and tools are available for the corrective action.

- In case of findings, reaction time to correct findings or apply a procedure for aircraft dispatch must be anticipated to limit operational or commercial impact for the next flights. Be prepared and practice from time to time possible findings with the technical data at your disposition. Very often the similar findings are noticed.

- Leaks of hydraulic, fuel or water/waste – AMM Limits not to exceed are indicated for Fuel, Hydraulic leaks noted during visual inspection. Do not disregard minor indication of leakages which may get worse.

- Structural damages – Bird strikes and ground handling are one of the major causes. Proper inspection and damage assessment has to be performed.

Note: with the new type of carbon fuselage which is coming back to its initial shape after an impact, in case of slight doubt use the line check tool. - Scratches, dents, cracks or erosion have to be inspected and corrective action to be carried out in the best possible time.

- Lightning strikes – Even if not reported by the Flight Crew, keep always a look for missing static dischargers, the extremities and engine cowls for black spots on the point.

- Wear on tyres, brakes, and paint erosion.

- Missing aerodynamic seals, service doors or access panels – Refer to the CDL (Configuration Deviation List) for items which are allowed to be missing. The CDL list is found in the Flight Manual Chapter 6. A CDL item must be corrected within the shortest possible time.

- Proper installation, flushness, missing or deformed seals at the fuselage and wing.

- Check for the presence of service doors (in place and secured), access doors, panels, fuel caps, caps on the bleeding valves of the brakes and landing gear servicing points.

- An area with a weak point, exposed too long to an unusual condition can induce some other issues, wear and damages.