Air conditioning is provided in aircraft for the comfort of passengers. The same conditioned air is also used for cabin pressurization in the airplane.

- Air Conditioning System

- PACK

- Components

- Air supply

- Operation of PACK

- Air distribution

- Recirculation

- Temperature Control

Air Conditioning System in modern aircraft

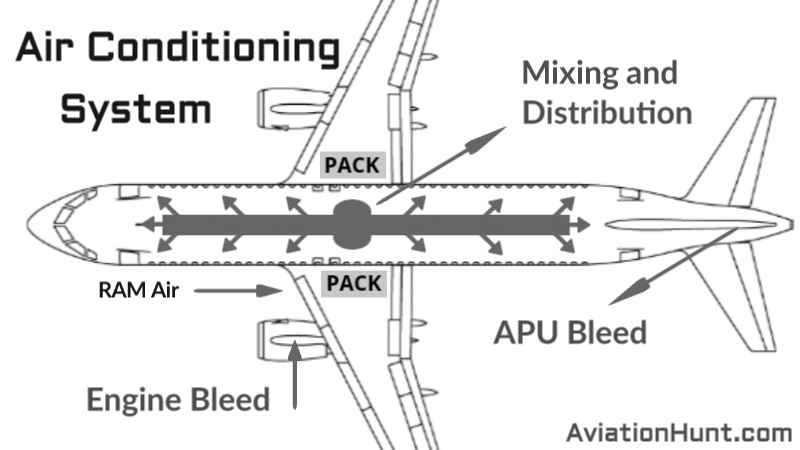

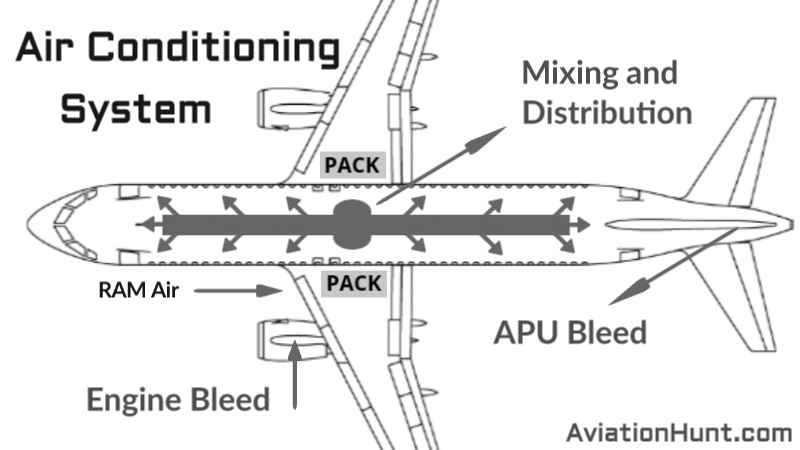

The air conditioning system is supplied by air processed through two packs that regulate airflow and temperature as required. Airplane air conditioning system mix hot and cold air to achieve the desired temperature.

Aircraft types vary, but the principles and operations of the air conditioning system are the same in all aircraft. The primary parts of the air conditioning system have these functions:

- Control fresh air flow for airplane pressurization and ventilation

- Control the flight compartment and passenger cabin temperature

- Recirculate cabin air for ventilation

Air Conditioning Pack

The pack allows bleed air to be cooled for conditioning the flight and passenger compartment. The air conditioning system is based on an Air Cycle Machine (ACM) cooling device, which is mostly used in turbine-powered aircraft. The air cycle system is often called the air conditioning package or Pack.

Usually, Air conditioning packs are located left and right wing to body area near the main landing gear of an airplane. Packs remove the excessive heat from bleed air entering to packs from the aircraft bleed air system and supplies air to the cabin at the desired temperature.

Air Conditioning Components

Major components of the air conditioning pack are:-

- Pack valve – Flow control and shutoff valve (FCSOV) controls the flow of bleed air into the pack.

- Primary Heat Exchanger – Cools the engine/APU bleed air.

- Secondary Heat Exchanger – Removes the heat of compression of the ACM.

- Air Cycle Machine (ACM) – An ACM comprising a compressor and a turbine mounted on the same shaft.

- Condenser – Condenser uses refrigerated turbine discharge air to cool incoming bleed air to a temperature low enough (below the dew point) for moisture condensation to occur.

- Re-heater – The reheater is used to raise the temperature of the air before it reaches the turbine inlet to vaporize any remaining water droplets for turbine protection.

- Water Extractor – The water extractor removes the water from the moisture produced by the condenser.

- Water Spray Nozzle – It is located at the secondary heat exchanger inlet and sprays on it water drained from the water extractor in order to increase the cooling capacity of the heat exchanger.

Air supply for Pack operation

The air cycle air conditioning system is supplied with air by the aircraft pneumatic system. In turn, the pneumatic system is supplied by bleed air tap-offs on each engine compressor section or from the APU pneumatic supply. Bleed air from the pneumatic manifold is directed into a primary heat exchanger of Packs.

Operation of Air Conditioning Pack

When bleed air goes through the primary heat exchanger, ram air removes some of the heat. This partially cool bleed air goes to the compressor section of the air cycle machine. The compressor section increases the pressure and temperature of the partially cool bleed air. This compressed-air goes to the secondary heat exchanger.

Air from the ACM compressor outlet flows through the secondary heat exchanger. A cross-flow of ram air removes heat before the air enters the ACM turbine inlet.

When the airplane is on the ground, the ACM impeller fan makes a low-pressure zone. This pulls air through the heat exchangers and up through the plenum to the impeller fan. Then the impeller fan sends the air through the diffuser and out the ram air exhaust.

When the airplane is in flight, the ram air pressure flows down the plenum and out the fan bypass check valve.

Bleed air that leaves the secondary heat exchanger goes through the hot side of the reheater. Air that goes through the reheater the first time is cooled by colder air from the condenser. The temperature of the bleed air increases as it goes through the reheater a second time and into the turbine section of the air cycle machine.

The reheater increases the temperature of the air in the air conditioning pack before it enters the turbine of the air cycle machine. This increases the efficiency of the turbine.

An Air cycle machine (ACM) decreases air temperature, by expansion through a turbine.

Air that leaves the turbine goes through the cold side of the condenser. Airflow from the condenser goes through a water extractor. The condenser decreases the temperature of the air in the air conditioning pack to below the dew point, changing water vapor into liquid. The water extractors remove moisture. This moisture goes to the water spray nozzle.

The water spray nozzle sprays the water into the ram air duct. This cools the ram air stream by evaporation and increases cooling efficiency.

Air distribution in the airplane cabin

The main air distribution system in aircraft gets air from Air conditioning packs, Ground conditioned air, and Recirculation system. The mix manifold collects and mixes air from any combination of the sources. The flight compartment gets conditioned air from the left pack and the mix manifold. The flight compartment receives conditioned air from the right pack if the left pack is not operational. Passenger conditioned air distribution gets air from the mix manifold. The air goes through riser ducts and up sidewalls to an overhead distribution duct.

Recirculation of cabin air

The recirculation system uses two fans to move air from the passenger compartment to the mix manifold. This system reduces the amount of air that the packs need to supply. This part of the A/C system recycles approximately 50 percent of the cabin air for ventilation purposes. This reduces the quantity of fresh air from the pneumatic system for ventilation. The left and right recirculation fans and filters are the primary components.

High-efficiency air filters are used in modern aircraft, which capture more than 99.9% of airborne in filtered air. They are similar to those used in hospital operating rooms.

Temperature control

The temperature control system has overheat switches in the supply ducts. The overheat switches give an indication and stop operation when the temperature is out of limits. Temperature bulbs in the passenger cabin and duct that monitor and send temperature data to the cabin temperature control panel. The temperature control panel shows air temperatures.

Air from the pneumatic system adds heat to a zone that needs warmer air. This warm bypassed air must be mixed with the cold air produced by the air cycle system so the air delivered to the cabin is a comfortable temperature. This is accomplished by the mixing valve.

The temperature controller compares the actual temperature signals received from the various sensors with the desired temperature input. An output signal is sent to a valve in the air cycle air conditioning system. This valve has different names depending on the aircraft manufacturer and design of the environmental control systems (i.e. Mixing Valve, Temperature Control Valve, Trim Air Valve). It mixes warm bleed air that bypassed the air cycle cooling process with the cold air produced by it.